X

Product Description

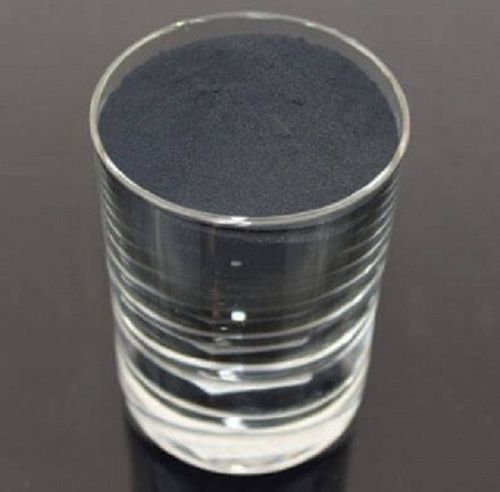

LSM-YSZComposite Cathode Ink

Product Code: 6201643

LSM-YSZ Composite Cathode Inks are excellent for fabricating your own Solid Oxide FuelCell (SOFC) with a composite cathode. The composite cathode inks have demonstrated better adhesion to the dense electrolyte surface which can enhanceyour overall cell performance. This ink is fabricated using a high-quality ink manufacturing processes and provides and a screen printable ink that is excellent for incorporating into your own cell manufacturing process.

Typical Use Guidelines:

- This is a great inkfor making cathode catalyst layers for SOFC applications.

- Stirring the ink before use is highly recommended. For best results, the inkshould be stirred with a spatula or a glass rod to achieve an even consistency prior to use.

- For making cathode catalyst layers that are well bonded to the electrolyte: Theink applied electrolyte is typically sintered at 100°C (until it looksdry), then sintered at 800°C for 1 hr, and then at 1150°C for 1hr. If an anode catalyst layer is also going to be applied (which wouldrequire a much higher sintering temperature than the this cathode), then it isrecommended that the anode catalyst layer to be bonded to the electrolytefirst. Exposing this cathode ink to sintering temperatures>1150oC would cause the densification and low performance and this needs to be avoided.

- For making electrical connections to a screen or wire:This ink is typicallyfired at 750oC or 850oC for 1 hour to ensure adhesion prior to testing at thedesired test temperature.

- This ink can be used for screen printing for generating electrical connections for wire attachments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

Other Products in 'Solid Oxide Fuel Cell Components' category

|

ULTRANANOTECH PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |