Product Description

Brand: FuMA-Tech

Product Code: 5041688

Fumasep FAA-3-20 is a non-reinforced Anion ExchangeMembrane (AEM) with very low resistance, high selectivity and highstability in pH acidic and basic environment. The polymer backbone forthis AEM is based on a hydrocarbon polymer material.

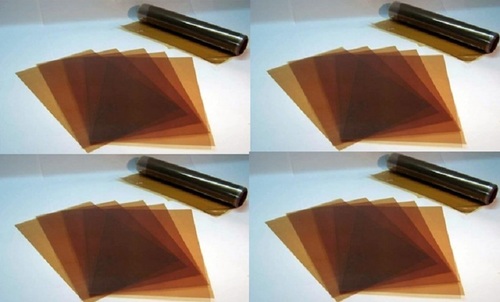

Fumasep FAA-3-20 membrane comes in a 20cm x 30cm sizesheet. The membrane is delivered in dry form and is the thin brown foil.

Fumatech membranes are highly sensitive to differences inhumidity and moisture content. Therefore the membranes can vary +/- 0.5cm fromthe original cut sizes. Also due to this sensitivity the manufacturer expectswrinkles to form, however soaking the membranes in deionized water will returnthe membranes to the full size planar state according to the manufacturer.

Fumasep FAA-3-20 Features:

Applications: Alkaline fuel cells without KOH or at lowKOH concentration. This membrane can also be used for other electrochemicalapplications that require the transfer of anions such as Cl-, Br-, sulfate, andetc.

Anion Exchange Membrane (AEM)

Stability Range for pH: 1 - 14

Thickness: 18 - 22 micrometers (0.709 -0.866 mil)

Size: 20cm x 30cm

Handling:

Keep membrane package closed / sealed when unused. Unpackmembrane only for direct use and process immediately after opening. Store,handle and process the membrane in a clean and dust-free area. Always wearprotective gloves when handling the membrane. Handle with care, be sure not topuncture, crease or scratch the membrane, otherwise leaks will occur. Allsurfaces which may get into contact with the membrane during inspection,storage, pretreatment and mounting must be free of sharp edges or angles.

Storage:

Dry form: Storage for long time scale (> 12 month) maybe done in dry state (sealed container). Wet form: Storage for short and mediumtime scale (hours up to several weeks) may be done in unsealed containers in0.5 1.5 wt% NaCl solution or comparable neutral pH electrolytes. For storageover a longer time period a sealed container is recommended using afore saidelectrolyte with ca. 100 ppm biocide (NaN3) to avoid biological fouling.

Pre-Treatmentand Conditioning:

The membrane is delivered in bromide form and dry form.Depending on application and cell design, assembling is possible in dry form(without pretreatment) or wet form. Before assembling in wet form put themembrane sample between stabilizing meshes / spacers (in order to avoidcurling) in NaCl solution - e.g. 0.5 M NaCl solution at T = 25 C for 72 hrsexchanging the solution several times. Do not let the membrane dry out sincemicro-cracks may likely occur during shrinkage.

For standard alkaline fuel cell / electrolysisapplications, the membrane should be converted into OH-form by treating it with0.5 1.0 M NaOH or KOH solution: Put the membrane sample in an aqueoussolution of 0.5 1.0 M NaOH or KOH for at least 24 h at 20C 30C. Afterrinsing with demineralised water (pH ~ 7) the membrane is ready to use. Useclosed container to avoid CO2 contamination (carbonate formation that mayaffect conductivity). The membrane in OH-form must be stored under wet /humidified and CO2-free conditions, avoid drying out of the membrane inOH-form. Long-term storage in dry conditions should be preferably done incarbonate, Cl- or Br-form.

For electrochemical CO2 reduction applications, theanion exchange membrane should be converted to the carbonate or bicarbonate formby treating the membrane initially with 0.1 to 0.5 M KOH or NaOH solution andthen with 0.1 to 0.5 M water soluble carbonate or bicarbonate salt solutions(such as potassium carbonate or potassium bicarbonate that is dissolved inde-ionized water or distilled water). Fully submerging the anion exchangemembrane into KOH or NaOH solution for 6 to 12 hours and then to the desiredcarbonate or bicarbonate salt solution for a period of 48-72 hours would besufficient to fully convert the membrane into either carbonate or bicarbonateform. After rinsing the membrane (which is in the carbonate form) withdeionized water or distilled water, it can be assembled inside theelectrochemical setup for electrochemical CO2 reduction experiments. Whilethe submersion of the membrane into the KOH or NaOH can be skipped, for suchsituations, a longer submersion time may be required in order to fully convertthe membrane to carbonate or bicarbonate form. Initial conversion to OH- formsignificantly improves the carbonate ion exchange process due to expanded poresizes.

For otherelectrochemical (electrodialysis, desalination, electro-electrodialysis,reverse electrodialysis, acid recovery, salt splitting, etc.) andnon-electrochemical applications, the membrane should be converted into theanionic form that is relevant for the intended application. For example,if the application is requiring the Cl- anions to be transferred through themembrane, then this anion exchange membrane needs to be converted into the Cl-form. In order to convert this membrane into Cl- form, it needs to besubmerged into a 1-2 M salt solution of NaCl or KCl (dissolved in deionizedwater) for a period of 24-72 hours and then rinsed with deionized water toremove the excess salt from the membrane surface. Or if the intendedapplication is requiring to transfer sulfate anions, then this anion exchangemembrane needs to be converted into the sulfate form prior to its assembly intothe cell. A neutral salt solution of Na2SO4 or K2SO4 wouldusually be sufficient to achieve the full conversion of membrane into thesulfate form after fully submerging the membrane into the salt solution for24-72 hours at room temperature.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Fuel Cell Membranes' category

|

ULTRANANOTECH PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |