Product Description

FumasepFAP-450

Brand: FuMA-Tech

Product Code: 5041638

Fumasep FAP-450 is a non-reinforced Fluorinated AnionExchange Membrane (AEM) with low resistance, high blocking capability ofvanadium ions, and high stability in acidic environment. The polymer backbonefor this AEM is based on a hydrocarbon polymer material.

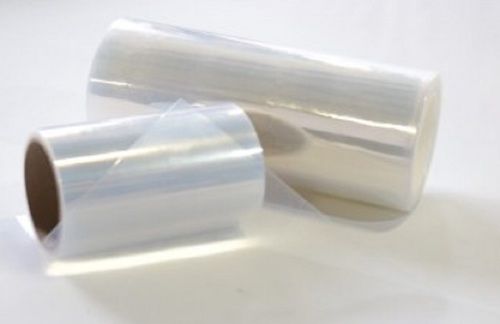

Fumasep FAP-450 membrane comes in either a 10cm x 10cm or20cm x 30cm size sheet. FAP-450 membrane is manufactured on the PET cover filmin order to prevent damages to the membrane during its shipment. The PETfoil is located only on one side of the FAP-450 membrane and it needs to beremoved from the membrane surface before testing or using the membrane. FAP-450 is transparent and more flexible than the PET cover film. Themembrane is ready for use when it arrives.

Fumatech membranes are highly sensitive to differences inhumidity and moisture content. Therefore the membranes can vary +/- 0.5cm fromthe original cut sizes. Also due to this sensitivity the manufacturer expectswrinkles to form, however soaking the membranes in deionized water will returnthe membranes to the full size planar state according to the manufacturer.

Fumasep FAP-450Features:

Applications: Redox-Flow Battery, e.g.Vanadium-Redox-Flow Battery (VRB), using aqueous acidicconditions. Another application that can benefit greatly from thismembrane is non-aqueous redox flow batteries that utilize organic solvents suchas acetonitrile, etc. The dimension change or swelling of the membrane fornon-aqueous redox flow battery applications would predominantly depend on thechemical composition of the electrolyte used. Mechanically reinforcedfluorinated anion exchange membranes would demonstrate increased mechanicalstability and lower solvent mediated crossover compared to non-reinforcedcounterparts for non-aqueous redox flow battery applications.

Type: Anion Exchange Membrane

Thickness: 50 micrometers (1.97 mil)

Sizes: 10cm x 10cm, 20cm x 30cm

Operation Range:

Acidic environment pH < 4, at pH > 4 the materialhas low ionic conductivity. The material is not stable in caustic environment(pH > 11). General temperature range is room temperature to 50C.

Handling:

Keep membrane package closed / sealed when unused. Store,handle and process the membrane in a clean and dust-free area. Use only new andsharp knives or blades, when cutting the membrane. Always wear protectivegloves when handling the membrane. Handle with care, be sure not to puncture,crease or scratch the membrane, otherwise leaks will occur. All surfaces incontact with the membrane during handling, inspection, storage and mountingmust be smooth and free of sharp projections.

Pre-Treatment and Conditioning:

The membrane is delivered in dry form. No pretreatment isrequired. However, membranes will expand and contract based on electrolytecontent.

Long Term Storage:

The membrane can be stored dry for anunlimited amount of time. However, the membrane has to be conditioned (washedand rinsed) prior to use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Fuel Cell Membranes' category

|

ULTRANANOTECH PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |