Product Description

Brand: FuMA-Tech

Product Code: 5041615

FumasepFAS-PET-75 is a PET reinforced Anion Exchange Membrane (AEM) with lowresistance, high selectivity, high mechanical stability, and high stability inpH neutral and acidic environments. The polymer backbone for this AEM isbased on a hydrocarbon polymer material.

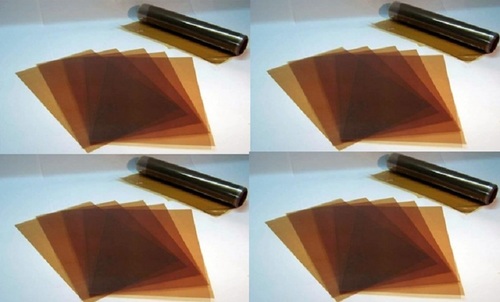

FumasepFAS-PET-75 membrane comes in either a 10cm x 10cm or 20cm x 30cm size sheetthat is delivered in a dry brown-foil form.

Fumatechmembranes are highly sensitive to differences in humidity and moisture content.Therefore the membranes can vary +/- 0.5cm from the original cut sizes. Alsodue to this sensitivity the manufacturer expects wrinkles to form, howeversoaking the membranes in deionized water will return the membranes to the fullsize planar state according to the manufacturer.

Fumasep FAS-PET-75 Features:

Applications: Electrodialysisfor demineralisation, desalination, acid recovery applications and others.

Anion Exchange Membrane

Stability Rang (pH) at 25C: 0 - 8

Thickness: 70 - 80 micrometers (2.76 - 3.15 mil)

Sizes: 10cm x 10cm, 20cm x 30cm

Handling:

Keepmembrane package closed / sealed when unused. Store, handle and process themembrane in a clean and dust-free area. Use only new and sharp knives orblades, when cutting the membrane. Always wear protective gloves when handlingthe membrane. Handle with care, be sure not to puncture, crease or scratch themembrane, otherwise leaks will occur. All surfaces in contact with the membraneduring handling, inspection, storage and mounting must be smooth and free ofsharp projections.

Storage:

DryForm: The membrane can be stored dry for an unlimited amount of time.However, the membrane has to be conditioned (washed and rinsed) prior to use.

WetForm: Storage for short and medium time scale (hours up to several weeks)may be done in unsealed containers in 0.5 - 1.5 wt% NaCl solution or comparableneutral pH electrolytes. For storage over a longer time period a sealedcontainer is recommended using afore said electrolyte with ca. 100 ppm biocide(NaN3) to avoid biological fouling.

Pre-Treatment and Conditioning:

Themembrane is delivered in bromide form and dry form. Depending on applicationand cell design, assembling is possible in dry form (without pretreatment) orwet form. For optimum performance it is recommended to rinse the membrane inNaCl solution (e.g. 0.5 M NaCl solution at 25C for 24 hrs) to remove anyadditive from the membrane. Place the membrane sample between stabilizingmeshes / spacers in order to avoid curling. Do not let the membrane dry outsince micro-cracks may likely occur during shrinkage.

If you have any concerns about storage,chemical stability and pretreatment before proceeding, please feel free tocontact us for further information.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Fuel Cell Membranes' category

|

ULTRANANOTECH PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |